Quality CD Welds are defined by a perfect balance of fusion depth and aesthetic finish, ensuring structural integrity without damaging the reverse side of the workpiece. In high-precision manufacturing, the margin for error is razor-thin; a single failure in the field can compromise entire assemblies and lead to devastating liability. Understanding the transition from a molecularly sound bond to a brittle, superficial attachment is the hallmark of an expert operator.

Why Quality CD Welds are Critical for Safety

The fundamental goal of any welding process is to create a joint that is stronger than the materials it connects. In Capacitor Discharge (CD) welding, this is achieved by discharging a high-voltage current through a small “timing tip” on the base of the stud, creating an instantaneous arc.

Engineering for Load Capacities

When a weld is executed correctly, the heat-affected zone (HAZ) is remarkably small, preventing the warping or weakening of the base metal. This allows engineers to specify thinner materials without sacrificing the pull-out or torque strength of the fasteners.

Avoiding Catastrophic Joint Failure

A “bad” weld often hides behind a facade of stability. While it may hold under static conditions, vibration and thermal cycling in industrial environments will quickly expose internal porosity or incomplete fusion, leading to sudden detachment.

| Safety Metric | Good Weld Characteristics | Bad Weld Risk |

|---|---|---|

| Tensile Strength | Exceeds stud material limits | Immediate shear failure |

| Structural Integrity | 360-degree molecular fusion | Intermittent bonding/Cracks |

| HAZ Impact | Negligible structural change | Brittle base metal zone |

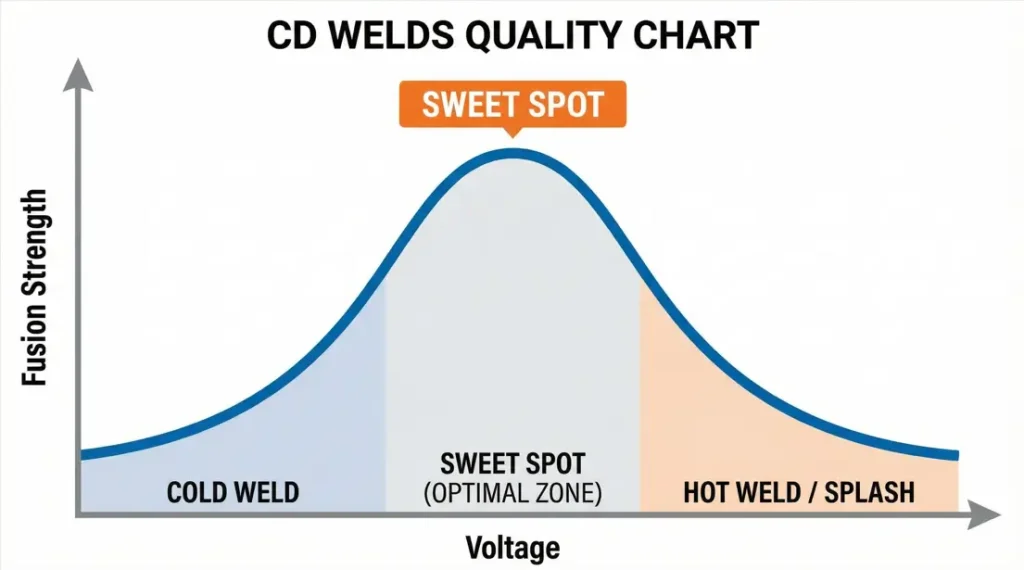

The Impact of Current Control on Fusion Depth

The energy stored in the capacitors of a stud welding machine must be precisely metered to match the diameter of the fastener and the gauge of the base metal.

Voltage Regulation and Energy Release

If the voltage is insufficient, the arc will not generate enough thermal energy to create a deep molten pool. This results in a “cold” attachment where the metal simply sticks to the surface rather than fusing into it. Conversely, excessive voltage creates an explosive energy release.

Optimizing the Heat-Affected Zone

Expert analysts look for the “sweet spot” on the energy curve. Ideally, the energy should be high enough to liquefy the timing tip and a microscopic layer of the base metal simultaneously, allowing them to intermix before the current ceases.

| Setting | Resulting Quality | Visual Indicator |

|---|---|---|

| Optimal Voltage | Full Molecular Bond | Small, uniform flash ring |

| Under-Voltage | Cold Adhesion | No visible flash; easy snap |

| Over-Voltage | Hot Splash | Erratic metal spray; soot |

Why Spring Pressure is the “Plunge” Factor

The mechanical action of the welding gun is just as vital as the electrical discharge. The internal spring pressure determines how quickly and forcefully the stud is driven into the molten metal pool.

Balancing the Plunge Rate

High spring pressure is often required for larger diameter studs to ensure they seat before the molten pool solidifies. If the pressure is too light, the stud may “hang up,” creating a gap that leads to a porous, air-trapped joint.

Timing and Arc Stability

The timing of the plunge must coincide exactly with the peak of the arc. If the spring is poorly calibrated, the stud enters the pool too late (after cooling starts) or too early (extinguishing the arc prematurely).

| Pressure Variable | Effect on Weld Quality | Recommended Adjustment |

|---|---|---|

| Too High | Material deformation/Thinning | Decrease spring tension |

| Optimal | Perfect seat/No porosity | Maintain factory specs |

| Too Low | Gap formation/Weak arc | Increase tension via gun dial |

Identifying “Cold” Errors in Capacitor Discharge

A cold weld is the most deceptive failure mode. It often occurs when using a specialized flux-ball fixing machine with incorrect settings or when the surface temperature of the workpiece is too low to facilitate fusion.

Signs of Incomplete Fusion

A cold weld is visually characterized by a total lack of “flash” (the tiny collar of metal at the base). The stud appears to be resting on top of the plate like a sticker rather than being integrated into it.

The 15-Degree Bend Test

To confirm a cold error, operators perform a destructive bend test. A good weld will cause the stud to bend or the base metal to tear; a cold weld will simply “pop” off, leaving the base metal surface completely clean and unmarked.

| Error Type | Primary Cause | Immediate Fix |

|---|---|---|

| Cold Joint | Low Capacitance/Voltage | Increase voltage settings |

| Non-Bond | Poor Grounding | Clean ground clamp area |

| Brittle Break | Contaminated Studs | Use high-quality fasteners |

What Causes the Erratic “Splash” in Hot Welds?

Hot welds are the result of an over-energized discharge that vaporizes too much material, creating a violent “splash” of molten metal around the fastener.

The Mechanics of Metal Spray

When the arc is too intense, the molten pool becomes too large and low-viscosity. When the stud plunges, it acts like a stone dropped into water, splashing the liquid metal away from the center where the bond is needed most.

Consequences of Excessive Heat

Beyond the messy appearance, hot welds often lead to “undercutting,” where the base metal becomes thinner around the perimeter of the stud. This significantly reduces the torque capacity of the fastener and can cause leaks in liquid-tight applications.

| Visual Sign | Technical Diagnosis | Structural Impact |

|---|---|---|

| Large Burrs | Voltage too high | Reduced aesthetic value |

| Soot/Char | Extreme over-current | Weakened grain structure |

| Pitting | Excessive arc time | Potential for corrosion |

How Surface Preparation Influences Integrity

Even the most advanced machinery cannot compensate for a contaminated workpiece. Our team at ZOC Machinery emphasizes this in our about us expertise section: “Cleanliness is the precursor to conductivity.”

Removing Oxides and Coatings

Oxidation, mill scale, and paint act as insulators. They prevent the timing tip from making a clean circuit, which causes “arcing-out” where the electricity jumps erratically, resulting in a failed, charred connection.

The Role of Degreasing

Oil and grease vaporize instantly under the heat of the arc, creating gas bubbles. These bubbles become trapped as the weld cools, leading to internal porosity that makes the joint look like Swiss cheese under a microscope.

| Contaminant | Weld Effect | Cleaning Method |

|---|---|---|

| Rust/Scale | Arc instability | Grinding/Sanding |

| Oil/Coolant | Porosity/Voids | Solvent degreasing |

| Zinc/Plating | Toxic fumes/Brittle weld | Surface removal at weld site |

Visual Indicators of a Perfect CD Connection

A “Good” weld is instantly recognizable by a trained inspector. It represents a synergy of electrical, mechanical, and metallurgical precision.

The Uniform Flash Ring

A perfect weld features a small, uniform collar of metal (flash) that extends 360 degrees around the base. This indicates that the stud was perfectly perpendicular and that the molten metal was forced outward evenly during the plunge.

Perpendicularity and Seating

The stud must be perfectly upright. A “leaning” stud indicates that the operator did not hold the stud welding gun straight, which creates a lopsided weld where one side is cold and the other is hot.

| Inspection Point | Good Result | Bad Result |

|---|---|---|

| Flash Symmetry | Equal 360° distribution | One-sided or missing |

| Reverse Side | No marking/minimal heat | Burn-through or dimpling |

| Alignment | 90° to surface | Tilted or skewed |

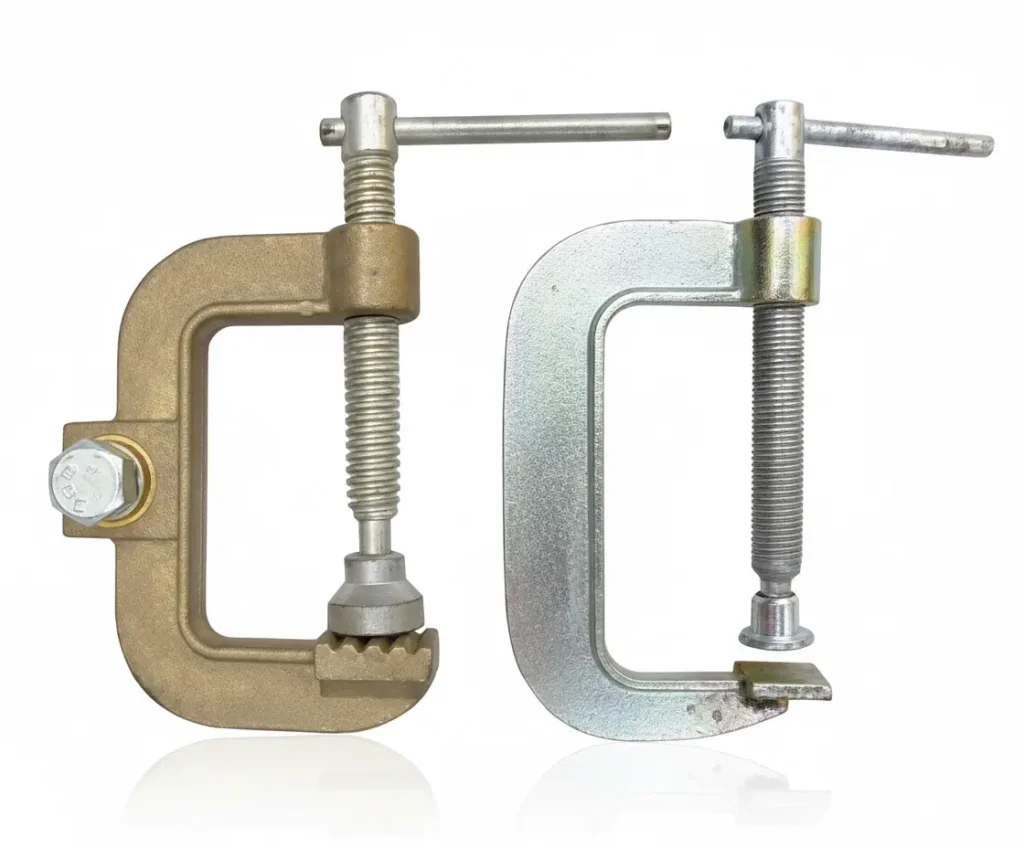

Why Grounding Accessories Dictate Consistency

The electrical circuit is only as strong as its weakest link, which is often the ground connection. Using a high-quality stud welding gun is useless if the return path for the current is inhibited.

Dual Grounding Strategies

For large workpieces, a single ground clamp can cause “arc blow,” where the magnetic field of the current pulls the arc to one side. Using two ground clamps placed equidistant from the weld site ensures a stable, vertical arc.

Maintaining Collet Conductivity

The collet inside the gun must grip the stud tightly. If the collet is worn or dirty, the current will arc inside the gun, damaging the equipment and stealing the energy needed for the actual weld.

| Accessory | Maintenance Requirement | Sign of Failure |

|---|---|---|

| Copper Collet | Replace every 5k-10k welds | Loose fit; internal arcing |

| Ground Clamp | Clean contact teeth daily | Heat buildup at the clamp |

| Cables | Check for frays/loose lugs | Dropping voltage settings |

Automation and the Path to Zero-Defect Production

To eliminate the “human factor,” many Tier-1 manufacturers are moving toward robotic CD welding systems. Automation provides the repeatability that manual operation simply cannot achieve over an 8-hour shift.

Robotic Repeatability

A robotic arm applies the exact same pressure at the exact same angle for every single weld. This level of consistency is critical for industries like automotive manufacturing, where thousands of studs are used per vehicle chassis.

Real-Time Monitoring

Modern automated systems can monitor the “voltage drop” during the discharge. If the machine detects an anomaly (like a missing stud or a contaminated surface), it can flag the part for inspection immediately, preventing bad welds from ever leaving the line.

| Method | Repeatability | Speed | QA Reliability |

|---|---|---|---|

| Manual | Variable | Moderate | Visual only |

| Semi-Auto | High | Fast | Digital tracking |

| Full-Auto | Exceptional | Very Fast | Real-time feedback |

Essential Maintenance Protocols for High Quality

Consistent weld quality is a byproduct of disciplined equipment maintenance. A neglected power unit will eventually fail to deliver the rated capacitance, leading to a slow decline in joint strength.

Daily and Weekly Checks

Operators should blow out the welding gun with compressed air to remove metallic dust and ensure the spring mechanism moves freely. Any friction in the gun’s sliding shaft will directly translate into inconsistent plunge timing.

Annual Calibration

Capacitors are consumable components. Over years of heavy use, their storage capacity can diminish. Annual calibration by a certified technician ensures that the energy displayed on your screen matches the actual output at the gun.

| Maintenance Task | Frequency | Objective |

|---|---|---|

| Gun Lubrication | Weekly | Smooth plunge action |

| Stud Tip Audit | Every batch | Ensure ignition consistency |

| Capacitor Test | Annually | Verify energy output |

Summary

Distinguishing between a good and bad CD weld is the difference between professional-grade manufacturing and amateur assembly. By strictly controlling voltage, spring pressure, and surface cleanliness, you can achieve joints that are functionally superior to the base materials themselves. At ZOC Machinery, we provide the precision tools and industrial expertise required to eliminate the variables that lead to failure. If you are ready to standardize your production quality or need technical assistance with your current welding setup, please contact us for a professional consultation.

FAQ

Is it possible to weld aluminum studs to steel using CD welding?

Absolutely not. Aluminum and steel have vastly different melting points and chemical properties; they will not form a molecular bond. You must match the stud material to the base metal material for a successful weld.

Why does my stud have a “one-sided” flash ring?

This is almost always a result of poor alignment. If the gun is held at an angle, the molten metal is forced out of one side only. Ensure the gun is 90 degrees to the surface.

Can I reuse a stud if the first weld attempt failed?

No. The timing tip is consumed during the first arc. Re-welding a used stud will result in a “cold” weld because there is no ignition point to start the arc properly.

How do I prevent the backside of my thin sheet metal from marking?

Reduce your voltage and increase your spring pressure slightly. The goal is to complete the fusion as quickly as possible to prevent heat from soaking through to the reverse side.

What is the most common reason for a sudden drop in weld quality?

A loose or dirty ground connection is the most frequent culprit. Always ensure your ground path is clean, tight, and as close to the weld site as possible.