Ceramic ferrules are used in stud welding as heat-resistant arc shields that contain molten metal, focus the arc energy, and protect the weld pool from atmospheric contamination during the drawn arc process.

Weld inconsistencies often plague large-scale industrial projects, leading to porous joints and weak structural bonds. These failures aren’t just minor setbacks; they can cause catastrophic structural collapses, expensive rework, and significant safety liabilities for your firm. Utilizing high-quality Ceramic Ferrules provides the precise thermal control and atmospheric shielding necessary to guarantee deep, repeatable, and code-compliant fusions every time.

What exactly are Ceramic Ferrules in stud welding?

Ceramic ferrules are disposable, refractory rings specifically engineered to shield the welding arc and mold the molten metal during drawn arc stud welding. These components are temporarily placed over the stud to serve as a mini-crucible, ensuring the intense heat is concentrated exactly where the fusion needs to occur.

The primary role of a ferrule

Think about this: without a dedicated shield, the electrical arc would wander and react violently with the surrounding air. The ferrule acts as a multi-functional tool that manages both the physical and chemical environment of the weld.

- Containment of the molten metal pool to prevent splatter.

- Shielding against oxygen and nitrogen contamination from the atmosphere.

- Concentration of heat energy to improve penetration depth.

- Controlled ventilation of expanding welding gases.

Key Takeaway: A ferrule is a sacrificial but mandatory component that transforms a raw electrical discharge into a precise metallurgical bond.

| Feature | Ceramic Ferrule Description |

|---|---|

| Material | High-temperature refractory ceramic |

| Function | Arc shielding and metal containment |

| Lifespan | Single-use (sacrificial) |

| Compatibility | Exclusively for drawn arc processes |

Why are Ceramic Ferrules vital for drawn arc welding?

Ceramic ferrules are vital because they stabilize the electrical arc and prevent the molten metal from leaking away from the stud base during the lifting phase. In the drawn arc process, the stud is lifted to strike an arc, creating a molten pool that must be physically contained to form a proper fillet.

How does the drawn arc process work?

But that’s not all; the ferrule also controls the cooling rate of the metal, which prevents the joint from becoming overly brittle. The synchronized movement of the gun and the protection of the ceramic ring work in tandem to create a permanent bond.

- Initial contact and lifting of the stud to strike the arc.

- Formation of a localized molten pool on the base plate.

- Return-spring plunging of the stud into the molten pool.

- Solidification of the metal inside the ferrule’s cavity.

Key Takeaway: These shields are the only mechanism ensuring the molten metal stays concentrated enough to fuse the entire diameter of the stud.

| Process Step | Role of Ceramic Ferrules |

|---|---|

| Arc Strike | Stabilizes the electrical arc path |

| Melting | Keeps molten metal concentrated |

| Plunging | Shapes the resulting weld fillet |

| Cooling | Slows cooling rate to prevent cracking |

How do Ceramic Ferrules ensure weld integrity?

Ceramic ferrules ensure weld integrity by creating a physical barrier that prevents porosity-causing gases from entering the weld zone. When using a professional stud welding machine , the ferrule keeps the molten steel pure and free from inclusions.

Why is gas ventilation important?

Here is the kicker: if the gases produced during the welding process cannot escape, they will form bubbles inside the metal, leading to internal voids. The small notches at the base of the ferrule are specifically designed to vent these gases while keeping the liquid metal inside.

- Reduces atmospheric contamination and oxidation.

- Minimizes internal weld porosity for better load bearing.

- Standardizes the size and shape of the weld fillet.

- Prevents “undercutting” which can weaken the base plate.

Key Takeaway: Using precision-engineered ferrules is the most cost-effective insurance policy against weld failure and inspection rejection.

| Integrity Factor | Ceramic Ferrule Impact |

|---|---|

| Porosity | Dramatically reduced by shielding |

| Strength | Increased by ensuring full fusion |

| Consistency | Standardized fillet dimensions |

| Safety | Reduces UV and spark exposure |

Can Ceramic Ferrules improve the weld aesthetic?

Ceramic ferrules improve the weld aesthetic by molding the excess molten metal into a uniform, symmetrical ring known as a fillet. This shaped collar not only looks professional but also provides a clean transition between the stud and the base material.

Do aesthetics reflect weld quality?

It gets better: a uniform fillet is actually the primary visual indicator used by inspectors to verify that a stud has fused correctly. A smooth, even ring of metal suggests that the arc was centered and the plunge was perfectly timed.

- Creation of a uniform and symmetrical fillet shape.

- Significant reduction of metal splatter on the surrounding workpiece.

- Clean transition that requires zero post-weld grinding.

- Easier visual identification of successful fusions.

Key Takeaway: A clean, molded fillet provides immediate visual confirmation to site inspectors that the weld meets structural standards.

| Aesthetic Element | Ferrule Benefit |

|---|---|

| Fillet Shape | Symmetrical and consistent |

| Surface Finish | Smooth and free of slag |

| Splatter | Contained within the ferrule walls |

| Inspection | Easier visual quality control |

Are Ceramic Ferrules required for all welding processes?

Ceramic ferrules are not required for Capacitor Discharge (CD) welding or short-cycle processes that utilize inert shielding gases. These processes operate on different physical principles where the weld time is too fast to require a physical ceramic barrier.

Why does CD welding skip the ferrule?

Why does this matter? Because CD welding is typically used for thinner materials where the weight and bulk of a ferrule would be impractical and unnecessary. The process is so rapid that atmospheric contamination is negligible compared to the drawn arc method.

- CD Welding: Uses no ferrule; relies on contact.

- Short Cycle: Often uses inert gas shrouds instead.

- Drawn Arc: Mandatory use of ceramic ferrules.

- Gas Arc: Uses specialized gas nozzles instead of ceramics.

Key Takeaway: You must always match your shielding method to the specific welding equipment and material thickness of your project.

| Process Type | Shielding Method | Ferrule Needed? |

|---|---|---|

| Drawn Arc | Ceramic Ferrule | Yes |

| Capacitor Discharge | None/Contact | No |

| Short Cycle | Inert Gas | Optional |

| Gas Arc | Gas Shroud | No |

Which Ceramic Ferrules fit your specific applications?

Choosing the right ceramic ferrules depends on the diameter of the stud and the specific geometry of the workpiece you are welding. You can find specialized accessories designed for flat plates, vertical beams, or even the inside corners of structural steel.

Are there different shapes for different jobs?

Think about this: using a standard flat-bottom ferrule on a curved pipe will allow the molten metal to leak out, ruining the weld. Specialized “contoured” ferrules are manufactured to fit the specific radius of your base material for a perfect seal.

- Standard Ferrules: For general flat-plate welding.

- V-Notched Ferrules: For welding onto the edges of angles.

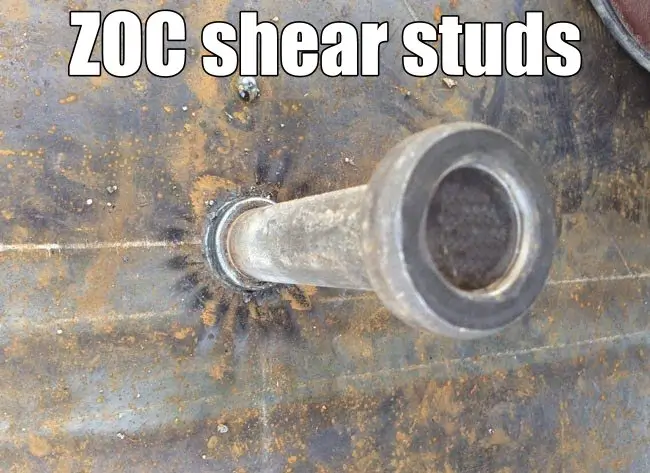

- Heavy-Duty Ferrules: For large diameter bridge shear studs.

- Threaded Ferrules: For specific industrial stud profiles.

Key Takeaway: Investing the time to select the specific ferrule for your workpiece geometry prevents costly leaks and rework.

| Application | Recommended Ferrule Type |

|---|---|

| Shear Connectors | Large Diameter/Heavy Duty |

| Flat Plate | Standard Circular |

| Inside Corners | Notched/Specialty |

| Vertical Walls | Extra-containment styles |

How to handle Ceramic Ferrules during the process?

Handling ceramic ferrules requires care because they are made of brittle refractory material that can easily crack or chip. When setting up your stud welding gun , ensure the ferrule grip holds the ceramic firmly without applying crushing pressure.

What happens if a ferrule is cracked?

It gets better: even a hairline fracture can allow the arc to escape or the molten metal to leak, resulting in an asymmetric and weak joint. Always inspect each ferrule for damage before sliding it onto the stud to ensure your shielding remains 100% effective.

- Inspect every ferrule for cracks or chips before use.

- Store ferrules in a dry environment to prevent moisture absorption.

- Ensure the ferrule is centered perfectly around the stud.

- Chip the ceramic away only after the weld has cooled slightly.

Key Takeaway: Treat your ceramic consumables as precision tools; any physical damage to the ring will compromise the final weld quality.

| Handling Rule | Why It Matters |

|---|---|

| Keep Dry | Prevents hydrogen embrittlement |

| No Cracks | Stops molten metal leakage |

| Snug Fit | Ensures the stud is centered |

| Post-Weld Removal | Reveals the final fillet |

What materials work best with Ceramic Ferrules?

Ceramic ferrules work best with mild steel, stainless steel, and high-strength alloys commonly found in heavy structural construction. These materials require the intense, concentrated heat and slow cooling rates that a ceramic shield provides for deep penetration.

Can you use them with aluminum?

The kicker is that while possible, aluminum is so reactive that most professionals prefer inert gas shielding over ceramic ferrules to prevent oxidation. For massive steel projects like bridges or skyscrapers, however, there is simply no better alternative for arc containment.

- Mild Steel: Perfect compatibility and thermal management.

- Stainless Steel: Requires clean ferrules to avoid carbon transfer.

- High-Strength Alloys: Benefits from the controlled cooling rate.

- Structural Steel: The industry standard for large shear studs.

Key Takeaway: Ceramic shields are the global standard for steel construction because they withstand temperatures exceeding 3,000°F.

| Material | Compatibility | Shielding Efficiency |

|---|---|---|

| Mild Steel | High | 100% |

| Stainless Steel | High | 98% |

| Inconel/Alloys | Medium | 95% |

| Aluminum | Low | Gas is preferred |

Do Ceramic Ferrules help reduce welding defects?

Ceramic ferrules help reduce welding defects by physically stabilizing the arc and preventing “arc blow,” which is the deflection of the arc caused by magnetic fields. By keeping the arc centered, the ferrule ensures that the heat is distributed evenly around the base of the stud.

How do they stop arc blow?

But that’s not all; the ceramic walls act as a physical guide that forces the molten metal to settle symmetrically, even if the gun is slightly tilted. This prevents the “one-sided” welds that often fail during bend tests or structural inspections.

- Prevents lopsided or incomplete weld fillets.

- Stabilizes the arc path against magnetic interference.

- Reduces the occurrence of slag inclusions in the metal.

- Controls the cooling rate to prevent internal stress cracks.

Key Takeaway: Using a high-quality ferrule is like having an insurance policy against the most common failures in industrial stud welding.

| Defect Type | Ferrule Prevention Method |

|---|---|

| Arc Blow | Magnetic and physical stabilization |

| Lopsided Fillet | Symmetrical molding cavity |

| Slag Inclusion | Gas venting through base notches |

| Cold Weld | Heat retention within the ring |

Where is the best place to source Ceramic Ferrules?

The best place to source ceramic ferrules is from a specialized manufacturer like About Us at ZOC Machinery, where we understand the metallurgical requirements of industrial fabrication. Quality suppliers ensure that the ceramic composition is consistent, preventing the rings from shattering prematurely under extreme heat.

Should you buy in bulk?

Think about this: running out of ferrules in the middle of a bridge deck installation can cost your company thousands of dollars in labor downtime. Because these are single-use consumables, maintaining a large, localized inventory is a strategic necessity for any major project.

- Look for ISO-compliant manufacturers with consistent quality.

- Ensure the sizing matches your specific brand of stud gun.

- Verify the venting design is optimized for your steel type.

- Always check for bulk-purchase discounts to lower project costs.

Key Takeaway: Partnering with a dedicated machinery expert ensures you always have the right consumables to keep your production lines moving.

| Sourcing Factor | What to Look For |

|---|---|

| Consistency | No variations in inner diameter |

| Heat Resistance | Ability to withstand 3000°F+ |

| Availability | Large stock for immediate shipping |

| Technical Support | Expertise in application matching |

Conclusion

Mastering industrial stud welding requires more than just a powerful machine; it demands a deep understanding of the consumables that make high-strength fusion possible. By utilizing premium ceramic ferrules, you eliminate the risks of porosity, weak joints, and messy finishes that compromise structural integrity. These small ceramic rings are the silent heroes of construction, providing the shielding, shaping, and stability required for world-class results. Whether you are working on a massive infrastructure project or specialized industrial components, the right ferrule ensures your work stands the test of time and passes every inspection.

Don’t let inferior consumables compromise your firm’s reputation for quality. If you are ready to elevate your welding standards and ensure every stud is a perfect fusion, contact us today to discuss your project requirements and find the perfect accessories for your fleet. Our vision is to provide the technical expertise and high-performance components that drive your success in the most demanding environments on earth.

FAQ

Can I reuse Ceramic Ferrules?

No, you cannot reuse them. Ceramic ferrules are designed to be sacrificial and usually shatter or become chemically contaminated after a single weld cycle.

What’s the best way to remove Ceramic Ferrules?

The best way is to wait a few seconds for the metal to solidify and then use a small hammer or the edge of a wrench to chip the ceramic away. It is designed to break off easily into several pieces.

How do I know if Ceramic Ferrules are the right size?

You should check the inner diameter of the ferrule against the diameter of your weld stud. It must fit snugly enough to center the stud but allow it to move freely during the plunge phase.

Can I weld without Ceramic Ferrules in a pinch?

You should never do this for drawn arc welding. Without the ferrule, you will experience dangerous metal splatter, extreme UV exposure, and a weld that will likely fail any structural strength test.

What’s the best storage for Ceramic Ferrules?

The best storage is a dry, temperature-controlled environment. Because ceramics are porous, they can absorb moisture from the air, which leads to “explosive” steam release and weld defects during the arc strike.