Ceramic ferrules play a critical role in drawn arc stud welding, particularly in structural and industrial applications where weld consistency, mechanical strength, and compliance with international standards are mandatory. For steel structure contractors, OEM manufacturers, and stud welding operators, understanding why ceramic ferrules are used is essential for ensuring reliable welding performance and long-term structural integrity.

As a manufacturer specializing in stud welding systems and ceramic ferrules, ZOC Machinery provides the following engineering-level explanation based on real production and on-site welding experience.

What Is a Ceramic Ferrule in Stud Welding?

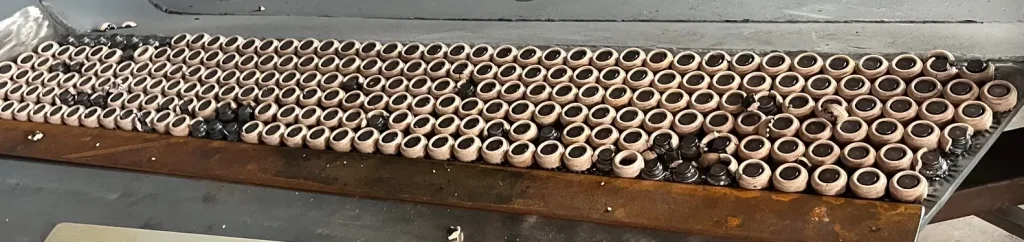

A ceramic ferrule is a precisely manufactured, heat-resistant ceramic ring positioned around the weld stud prior to ignition. During the drawn arc stud welding process, the ferrule serves as a temporary mold and arc control component, shaping the molten metal and protecting the weld pool until solidification is complete.

Ceramic ferrules are consumed during welding and removed after cooling, leaving a uniform weld collar that meets structural requirements.

Core Functions of Ceramic Ferrules

Arc Containment and Stability

During ignition, the electric arc generates extremely high temperatures. The ceramic ferrule confines the arc within a controlled space, preventing arc wandering and minimizing spatter. This stable arc environment is essential for achieving full fusion between the stud and base material.

Formation of a Uniform Weld Collar

One of the most visible indicators of weld quality is the symmetrical weld collar formed around the stud. The internal geometry of the ceramic ferrule guides molten metal evenly around the stud shaft, ensuring:

- Consistent collar height

- Uniform metal distribution

- Reduced undercut risk

A properly formed collar is often required for visual inspection and bend testing.

Protection of the Molten Weld Pool

The ceramic ferrule shields the molten metal from atmospheric contamination during the critical cooling phase. By limiting exposure to oxygen and nitrogen, it helps prevent:

- Porosity

- Oxidation defects

- Weak metallurgical bonding

This protection is especially important in outdoor construction environments.

What Happens If Ceramic Ferrules Are Not Used?

In drawn arc stud welding applications, omitting ceramic ferrules can lead to serious weld defects and inspection failures, including:

- Irregular or missing weld collars

- Excessive spatter and arc blow

- Incomplete fusion at the stud base

- Failure in bend tests and shear tests

- Increased rejection rates during quality inspections

For structural steel projects, these issues directly affect load-bearing performance and project safety.

Compliance With International Welding Standards

Ceramic ferrules are widely specified in international stud welding standards, including:

- AWS D1.1 / D1.1M – Structural Welding Code (Steel)

- ISO 13918 – Studs and ceramic ferrules for arc stud welding

- EN ISO 14555 – Arc stud welding of metallic materials

Using compliant ceramic ferrules helps ensure welds meet regulatory and third-party inspection requirements in global infrastructure projects.

Manufacturer Perspective: Why Ferrule Quality Matters

From a manufacturing standpoint, ceramic ferrule quality directly influences welding consistency. Key factors include:

- Dimensional tolerance: Inner diameter and height accuracy affect collar symmetry

- Material composition: Determines thermal resistance and fracture behavior

- Batch consistency: Ensures stable results across high-volume production

Low-quality or inconsistent ferrules often result in unstable arcs and variable weld appearance, even when using high-performance stud welding machines.

Typical Applications Using Ceramic Ferrules

Ceramic ferrules are standard in drawn arc stud welding across industries such as:

- Steel structure and high-rise construction

- Bridges and infrastructure projects

- Power plants and industrial facilities

- Shipbuilding and offshore platforms

- Heavy machinery manufacturing

They are commonly used with shear studs, threaded studs, anchor studs, and other structural fasteners.

Who This Information Is For

This guide is intended for:

- Steel structure contractors

- Stud welding operators and supervisors

- OEM manufacturers and fabricators

- Project engineers and quality inspectors

Understanding the role of ceramic ferrules helps ensure welding processes remain compliant, efficient, and structurally reliable.

Conclusion

Ceramic ferrules are not just accessories; they are the guardians of weld quality. They control the molten metal, shield against defects, and ensure every connection meets rigorous safety standards. At ZOCMachinery, we don’t just sell parts; we sell peace of mind. With factory-direct pricing, global logistics, and ISO-certified quality, we empower you to build with confidence.

Ready to secure your project’s success? Stop overpaying for consumables. Contact ZOCMachinery today for a quote on premium stud welding systems and ceramic ferrules—delivered straight from the factory to your site.

FAQ

Q1: Can I reuse a ceramic ferrule for multiple welds?

No, you cannot. Ceramic ferrules are designed as single-use consumables because they experience significant thermal shock and must be physically broken off to inspect the weld fillet properly.

Q2: How do I know if my ferrules are damp?

If you hear a “pop” or see excessive porosity in the weld, they might be wet. Damp ceramics release steam into the arc; always store them in a dry, sealed container to prevent this defect.

Q3: What is the best way to remove the ferrule after welding?

Wait until the weld metal has solidified and turned from red to black. Then, simply tap the ferrule with a small hammer or chipping tool to shatter the brittle ceramic ring.

Q4: Can I weld without a ferrule if I use shielding gas?

It depends on the specific process. While gas shielding works for short-cycle welding on thin sheets, heavy-duty drawn arc welding on structural steel requires ferrules to shape the fillet and contain the large molten pool.

Q5: How do I choose the correct ferrule size?

You must match the ferrule strictly to the stud diameter and application, such as flat versus through-deck. Refer to the stud manufacturer’s datasheet or contact ZOCMachinery’s support team to ensure perfect compatibility.