A good weld is defined by full material fusion, a uniform flash ring, and strict adherence to mechanical specifications like Length After Weld (LAW). In high-volume industrial production and shipbuilding, the integrity of your fastening points determines the safety and longevity of the entire structure. By prioritizing precision in every cycle, you eliminate the risks of catastrophic failure and costly rework. This guide provides the technical insights you need to optimize your production line and ensure 100% reliability.

Why is stud welding quality critical for safety?

High-quality stud welding quality is essential for safety because it ensures that fasteners act as integrated load-bearing components rather than mere surface attachments. When you operate in high-stakes environments like bridge construction, a single failure can lead to severe structural collapse. Ensuring joint integrity is your primary defense against professional liability and expensive insurance claims.

Does joint integrity impact overall safety?

- Absolutely: A homogeneous bond prevents fasteners from loosening under extreme vibration or mechanical stress.

- The standard: The fastener must become an integral part of the parent metal to handle rated loads.

How do failed studs affect liability?

- The truth is simple: Unreliable welds result in expensive litigation and irreparable damage to your B2B reputation.

- Risk mitigation: Rigorous quality control is your first line of defense against structural failure claims.

Key Takeaway: Safety in heavy industry is non-negotiable and starts with 100% weld reliability at every fastening point.

| Safety Factor | Industrial Impact | Risk Level |

|---|---|---|

| Structural Bond | Prevents detachment under load | Critical |

| Vibration Resistance | Ensures longevity in infrastructure | High |

| Component Integrity | Reduces maintenance and rework | Essential |

How does penetration affect welding quality?

Deep fusion penetration defines stud welding quality by creating a metallurgical bond where the stud and base metal become a single, inseparable unit. Achieving this requires precise energy delivery from a calibrated stud welding machine to melt both the stud tip and the parent metal simultaneously. Shallow penetration often results in “cold welds” that may look acceptable but fail instantly under minimal tension.

Is full fusion achievable every time?

- You bet: Consistent voltage and timing settings allow you to reproduce high-strength bonds across thousands of cycles.

- Consistency: Automated power regulation ensures the arc energy remains stable regardless of power grid fluctuations.

Can you detect shallow penetration visually?

- Look closely: A lack of base metal “pull” during destructive testing usually indicates the arc didn’t penetrate deeply enough.

- Warning signs: If the stud breaks off cleanly from the plate with no crater, your penetration is insufficient.

Key Takeaway: Strength is found below the surface; deep fusion is the only way to guarantee the mechanical load capacity of your fasteners.

| Penetration Depth | Resulting Bond Type | Quality Status |

|---|---|---|

| < 1.0mm | Surface Adhesion (Cold Weld) | Fail |

| 1.5mm – 3.0mm | Homogeneous Fusion | Pass |

| > 4.0mm | Potential Burn-through | Warning |

What visual signs confirm stud welding quality?

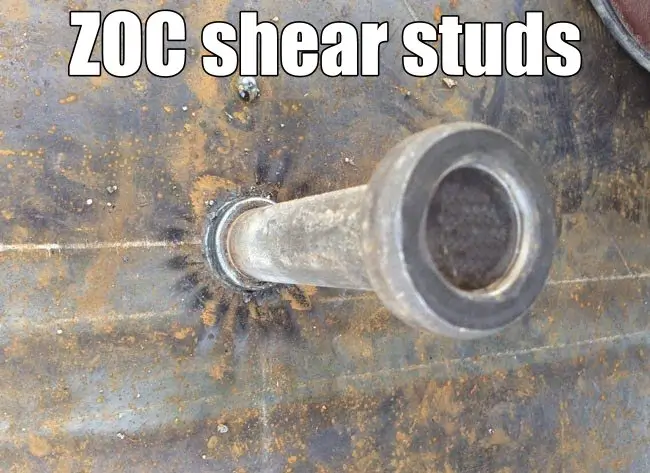

The most reliable visual signs of stud welding quality include a consistent 360-degree flash ring and a perfectly perpendicular stud orientation. You should inspect every weld for a uniform “collar” of molten metal, which indicates the arc was centered and the plunge force was adequate. Any tilt or uneven flash suggests a setup error that will compromise the joint’s mechanical stress distribution.

Does the flash ring look uniform?

- Check this: A complete circle around the base confirms that the molten pool was contained and distributed evenly.

- Avoid defects: Gaps in the flash ring often point to “arc blow” or improper ferrule seating.

Is the stud standing perfectly vertical?

- The key is: Verticality ensures that shear and tension loads are distributed according to the original engineering design.

- Alignment: Even a slight tilt can reduce the effective strength of the fastener by more than 20%.

Key Takeaway: Visual consistency is the fastest indicator of a healthy, repeatable welding process on the production floor.

| Visual Indicator | Ideal Condition | Error Meaning |

|---|---|---|

| Flash Ring | 360° Uniform Fillet | Balanced heat/pressure |

| Stud Angle | 90° Perpendicular | Correct operator handling |

| Surface Color | Blue/Grey (Minimal Charring) | Proper arc timing |

How does the gun impact welding quality?

Your applicator’s performance directly dictates stud welding quality by controlling the critical lift, timing, and plunge velocity of the welding cycle. Even the most advanced power source cannot compensate for a poorly maintained stud welding gun with worn internal springs or dampeners. Precise mechanics ensure the stud is “plunged” into the molten pool at the exact millisecond required for optimal fusion.

Are your plunge and lift settings correct?

- Think about it: Incorrect lift heights create unstable arcs, leading to porosity and weakened structural bonds.

- Precision: The gun must lift the stud to a specific height to maintain the arc gap before the final plunge.

Is consistent pressure being applied?

- Here is why: Uniform spring tension in the gun ensures the stud seats firmly into the parent metal every time without splashing.

- Maintenance: Regularly check that the internal piston moves freely without friction or sticking.

Key Takeaway: The gun is the primary interface for quality; maintain its mechanical precision to ensure consistent, high-performance results.

| Gun Component | Role in Quality | Maintenance Interval |

|---|---|---|

| Internal Spring | Controls plunge force | Every 50,000 cycles |

| Lift Mechanism | Defines arc length | Daily calibration |

| Cable Connections | Prevents voltage drops | Weekly inspection |

Can base metals degrade stud welding quality?

Surface preparation and material matching are fundamental to stud welding quality, as contaminants can act as insulators and introduce chemical weaknesses. You must grind the base metal to a bright finish to remove oil, rust, or mill scale that would otherwise cause arc instability. Additionally, pairing dissimilar metals without specialized settings can create brittle intermetallic layers that crack during the cooling phase.

Is the surface free of scale and oil?

- It is essential: Pure electrical conductivity is only possible when the contact point is stripped of all non-conductive debris.

- Best practice: Use a mechanical grinder to achieve a “white metal” finish for the most reliable electrical path.

Are you matching stud and plate materials?

- Keep in mind: Using the correct accessories and material-specific studs prevents chemical imbalances in the weld pool.

- Pro tip: Stainless steel studs require different lift and plunge settings than mild steel to manage heat dissipation.

Key Takeaway: A clean surface is the foundation of a high-strength weld; never compromise on preparation if you want to avoid structural failure.

| Contaminant | Impact on Weld | Solution |

|---|---|---|

| Mill Scale | Causes arc wandering | Grind to bright metal |

| Surface Oil | Introduces porosity (bubbles) | Solvent degreasing |

| Zinc Coating | Causes brittle joints | Remove coating at weld site |

Does equipment calibration ensure welding quality?

Regularly verifying your power source settings and ground connections directly ensures high stud welding quality. Think about this: even a slight deviation in voltage can lead to a brittle bond. You must use precision meters to check that the actual output matches your machine’s digital display. This proactive approach prevents costly structural failures before they ever happen.

- Inspect cables for insulation wear.

- Verify timer accuracy with an oscilloscope.

- Check ground clamp tension for stability.

- Monitor amperage consistency across cycles.

Maintaining Arc Precision

You need to understand how drawn arc stud welding relies on millisecond timing. If the lift height is off by even a fraction, the arc will be unstable. The result? A weak weld pool that lacks the necessary deep penetration for heavy-duty applications.

Key Takeaway: Precise timing is the heartbeat of a strong metallurgical bond.

The table below outlines the critical calibration parameters that operators must monitor to maintain peak performance.

| Calibration Factor | Target Metric | Impact on Quality |

|---|---|---|

| Voltage Accuracy | +/- 2% Variance | Prevents undercut and splatter |

| Timer Response | Millisecond precision | Ensures consistent fusion depth |

| Lift Height | Exact millimeter spec | Stabilizes the electrical arc |

Analysis: Equipment drift is often the silent killer of structural integrity, making scheduled recalibration the most effective preventive measure in any fabrication shop.

How do ferrules protect your stud welding quality?

Ceramic ferrules preserve stud welding quality by concentrating the heat of the arc and shielding the molten pool from atmospheric contamination. Here is why they matter. Without a ferrule, the molten metal would scatter, leaving you with an uneven and porous connection. The ferrule also shapes the “flash” or fillet at the base, which is a key indicator of a successful weld.

- Containment of molten metal.

- Reduction of oxidation and porosity.

- Shaping of the reinforcement fillet.

- Protection from external drafts or wind.

Arc Shielding Requirements

When you are performing cd stud welding on thinner materials, the need for ferrules changes depending on the specific process. However, for larger diameters, the ceramic shield is non-negotiable for safety and strength. It ensures the heat stays exactly where it belongs—in the weld zone. This prevents the arc from wandering and damaging the surrounding base metal.

Key Takeaway: Never skip a ferrule if the project specifications call for high-load capacity and aesthetic flash.

Using the correct ferrule size is just as important as the weld settings themselves, as shown in the comparison below.

| Ferrule Type | Primary Function | Best Use Case |

|---|---|---|

| Standard Ceramic | Flash containment | General construction |

| Reduced Fillet | Minimal base footprint | Narrow clearances |

| Gas Shielded | High-purity protection | Specialized alloy welding |

Analysis: The ferrule acts as a disposable crucible, essentially creating a controlled environment that mimics a miniature foundry at the point of contact.

How can you test for high welding quality?

Mechanical tests like the bend test provide definitive proof of stud welding quality by stressing the bond to its breaking point. Bottom line? A good weld must be stronger than the stud itself. If the fastener bends to a 30-degree angle without the weld failing, you know your settings are correct. This gives you the confidence that the joint will hold under real-world stresses.

- Visual inspection of the fillet.

- Torque testing for threaded fasteners.

- Hammer bend tests for structural studs.

- Tensile testing in laboratory settings.

Destructive vs. Non-Destructive Testing

In drawn arc stud welding, a visual check is often the first line of defense. You are looking for a 360-degree, clean fillet with no signs of undercut or porosity. While non-destructive torque tests are great for production, nothing beats the bend test for verifying the initial setup. It reveals the hidden flaws that a simple glance might miss.

Key Takeaway: Testing early and often prevents a single bad setting from ruining an entire production run.

The following testing methods are industry standards for ensuring that every fastener meets the required safety margins.

| Test Method | Procedure | Success Criteria |

|---|---|---|

| Bend Test | Strike stud to 30° angle | No cracking at the weld base |

| Torque Test | Apply specified foot-pounds | No rotation or stud shearing |

| Visual Check | 360° fillet inspection | Full fusion with no voids |

Analysis: High-quality testing protocols shift the focus from “hoping it holds” to “knowing it works,” which is the hallmark of professional metal fabrication.

Does material thickness impact stud welding quality?

Maintaining the correct ratio between the fastener diameter and the base plate depth is a critical factor for stud welding quality. If your base metal is too thin, you risk “burn-through” or severe distortion of the material. Conversely, a very thick plate acts as a heat sink, potentially sucking away the energy needed for full fusion. You must balance your power settings to account for the thermal mass of the workpiece.

- Minimum 1:3 stud-to-plate ratio for CD.

- Minimum 1:2 stud-to-plate ratio for Arc.

- Adjust amperage for high heat-sink metals.

- Support thin plates to prevent bowing.

Managing Heat Dissipation

When working with cd stud welding, the extremely short discharge time helps protect thin-gauge sheets from damage. The arc happens so fast that the heat doesn’t have time to travel through the metal. This allows you to weld studs to the backside of painted or finished surfaces without leaving a mark. It is a delicate balance of physics and electrical engineering.

Key Takeaway: Base material thickness dictates the welding process you choose and the power you must apply.

Choosing the right approach based on the thickness of your metal prevents structural deformation and ensures a clean finish.

| Base Metal Depth | Recommended Process | Common Risk |

|---|---|---|

| Under 1/8 inch | CD Welding | Burn-through/Marking |

| 1/8 to 1/4 inch | Short Cycle Arc | Moderate Distortion |

| Over 1/4 inch | Drawn Arc | Insufficient Fusion |

Analysis: The thermal conductivity of the base metal is often overlooked, but it is the primary variable that determines whether the weld pool reaches the necessary temperature.

Why is consistency vital for welding quality?

Achieving a repeatable result across every single fastener is the ultimate goal of stud welding quality. Imagine this: a bridge deck with thousands of studs where only half are properly fused. That is a recipe for disaster. Consistency ensures that the load is distributed evenly across all fasteners, preventing localized failures that could lead to a total collapse.

- Use automated feed systems.

- Implement robotic arms for precision.

- Standardize operator training.

- Use high-quality, uniform studs.

The Role of Automation

Modern drawn arc stud welding systems often use CNC or robotic integration to remove human error. By automating the plunge and lift cycles, you ensure that every weld is a carbon copy of the last. This is especially important in high-volume industries like automotive or shipbuilding. The more you can remove variables, the higher your overall yield will be.

Key Takeaway: Reliability is built through the elimination of variables in the welding environment.

Standardizing your workflow leads to a measurable increase in both speed and safety, as shown in the table below.

| Variable | Manual Control | Robotic Control |

|---|---|---|

| Gun Pressure | Subjective to operator | Digitally constant |

| Vertical Alignment | Visual estimation | Laser-guided precision |

| Cycle Repeatability | Variable by fatigue | 99.9% consistent |

Analysis: True quality is not measured by the strength of your best weld, but by the reliability of your weakest one.

Conclusion: Achieving Industrial Excellence in Stud Welding

Maintaining superior stud welding quality is a systematic process that integrates high-precision equipment with rigorous operational standards. To ensure 100% reliability in your fastening processes, you must prioritize proper surface preparation, ensuring base metals are ground to a bright finish to eliminate contaminants. Furthermore, the use of specialized accessories, such as ceramic ferrules for shaping the weld fillet and flux balls for deoxidizing the weld pool, is non-negotiable for heavy-duty applications. Consistency is finally secured through the calibration of welding guns and power sources, alongside post-weld verification methods like “Length After Weld” (LAW) measurements and mechanical bend tests.

We believe that in the world of industrial construction, there is no margin for error. Excellence is defined by the structural integrity of every single bond and the elimination of costly rework. At ZOC Machinery, we are committed to providing the heavy-duty equipment and expert insights you need to excel in every project.Our commitment is to provide the precision engineering and high-performance tools required to turn every fastening point into a pillar of safety and efficiency. To elevate your production standards and secure your infrastructure, contact us today to find the ideal welding solution for your specific requirements.

Frequently Asked Questions

How do I know if my weld penetration is sufficient?

Successful penetration is confirmed when a mechanical test pulls a “slug” of the parent metal. If the stud breaks away cleanly from the surface without taking any base metal with it, the bond is shallow and the weld is considered a failure.

What’s the best way to prevent porosity in the weld pool?

The most effective method is thorough surface grinding to achieve a bright metal finish. Removing rust, oil, and mill scale eliminates the primary sources of gas pockets and chemical impurities that weaken the fusion zone.

Can I achieve high-quality results without using a ceramic ferrule?

No, ferrules are essential for structural integrity. They act as a mold to shape the molten metal into a uniform fillet and provide a vital shield against atmospheric contamination during the arc cycle.

Is it possible to maintain quality when welding onto dissimilar metals?

It is possible but requires specialized settings and specific stud alloys. Attempting to weld mismatched materials without technical adjustments usually results in a brittle intermetallic layer that will fail under mechanical stress.

How do I ensure my welding gun settings remain consistent throughout a shift?

Implement a routine calibration schedule for lift and plunge settings. Regularly inspecting internal springs and dampeners ensures that the mechanical force applied during the “plunge” phase remains identical for every cycle.